The Custom Tooling Advantage

At EB Industries, we prefer to custom design and fabricate our own tooling for our customers’ projects.

- Custom tooling allows for higher production speed and faster turnarounds;

- Properly made tooling ensures a good fit-up of components for strong, high quality welds and less failures in the field.

We also keep a “tooling library”, so time isn’t wasted shipping tooling from one location to another. We keep it in-house. We can access it quickly, get your parts into a welder quickly, and get your finished pieces to you when you need them.

Custom Tooling for Electron Beam Welding

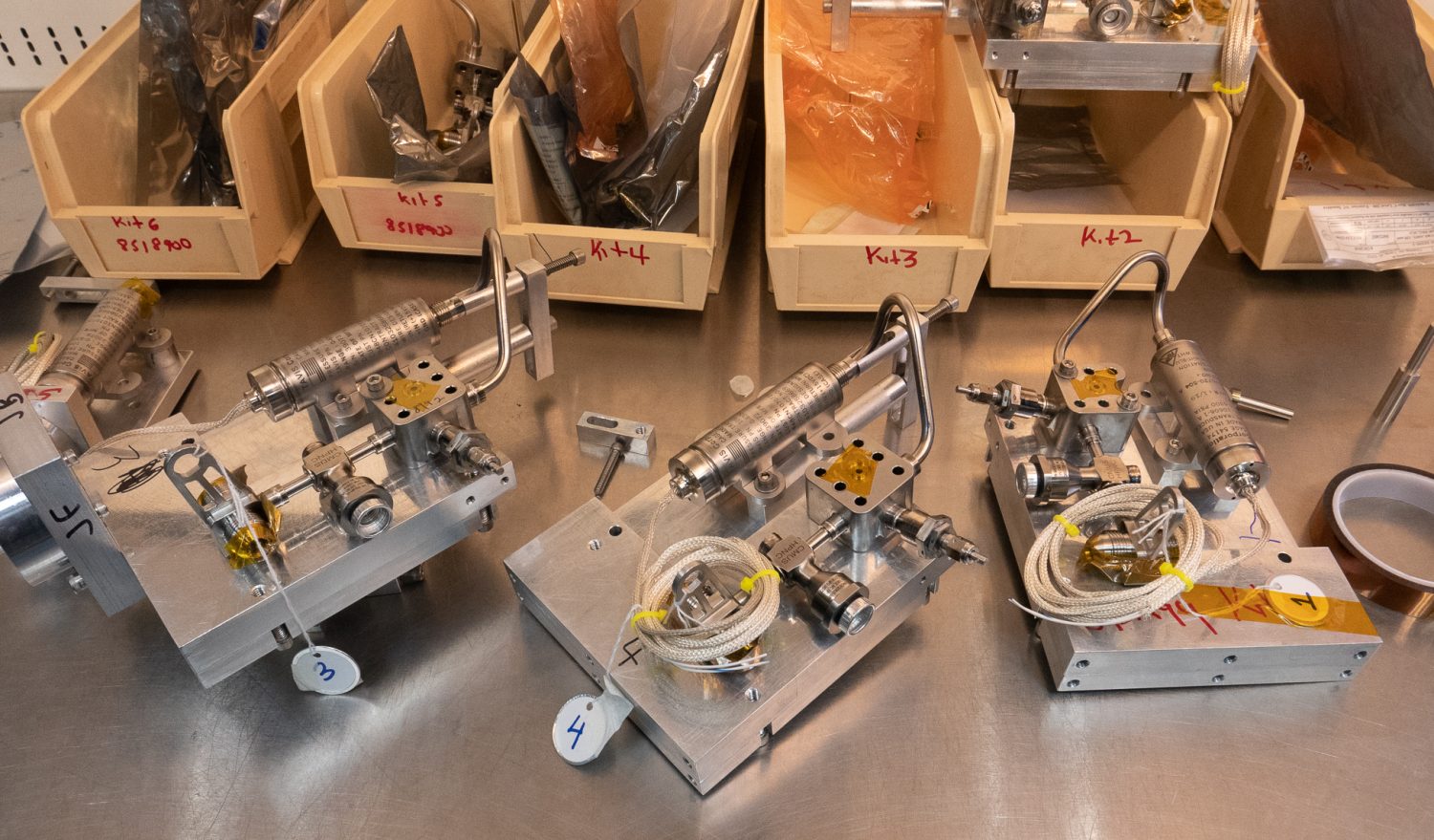

Electron beam welding requires moving parts into and out of a vacuum chamber. The welding process can’t go any faster than the amount of time it takes to load parts into the chamber and then pump all the air out. Further, an electron beam is generally fixed, which means parts have to be moved into position under the beam, and in many cases, maneuvered while the beam is on to complete the weld. Obviously, if all of this can happen — getting the part in place and then moving it during the weld — while maintaining a vacuum, the result is a more efficient process. This necessitates some very complex tooling.

Our engineers design our tooling to maximize the number of parts in the chamber during a vacuum cycle, while making sure each area to be welded can be cleanly sighted by the electron beam. The tooling must also hold parts securely enough so that they aren’t shaken out of alignment when the fixture rotates, slides, or in any way moves during the welding process. Finally, our engineers make the loading and unloading of the parts from the tooling as fast as possible.

Our electron beam welding custom tooling is interchangeable between our EB welding stations so that jobs can be run on multiple machines for faster production. It’s computer controlled and integrated into our CNC tables so movements and parameters can be stored and easily recalled. We also maintain a “tooling library” so that repeat orders can be quickly set-up and processed.

Custom Tooling for Laser Welding

Laser welding typically isn’t constrained by vacuum chamber requirements, but parts to be laser welded still have to fit up correctly, still have to be held securely and production speed is almost always a concern of our customers.

We work on a wide range of laser welding projects, from tiny medical implants to huge stainless steel piping used for MRI and NMR scans of oil wells. We custom design and fabricate tooling for the majority of our laser welding work, regardless of if it is done manually, with some automation, or fully automated in our 5 axis station.

Glove box laser welding applications can be similar to EB welding applications in that parts are moved in and out of a controlled environment. Complicating many glove box applications is a small size of the parts and access issues arising from properly viewing and monitoring weld areas. Our tooling design takes all of this into account.

Like our specialized EB welding tooling, we maintain stock in-house of all our laser welding tooling so we can turn around repeat orders quickly.

Toolmaking

EB Industries has a complete machine shop in-house along with staff machinists. From computer designed and milled fixtures to items that have to be made predominantly by hand, our shop has the equipment, along with experienced personnel, to create any tooling needed.