What’s Special About AMS 2680

Aerospace Material Specification (AMS) specification 2680, published by the SAE, defines the procedures and requirements for joining metals and alloys using the electron beam welding process for fatigue critical applications. The standard specifies that all welds be full-penetration welds to avoid stress concentrations and that procedures are designed to minimize porosity and other weld defects. It is the standard for welds when “the failure of which could cause loss of the aerospace vehicle or one of its major components, loss of control, or significant injury to occupants of a manned aerospace vehicle, but usage is not limited to such applications” (AMS 2680 Section 1.2).

Welding to AMS 2680 presents many design and weld challenges, and understanding the advantages and disadvantages of the three main weld joints allowed by the standard is key to successfully meeting it.

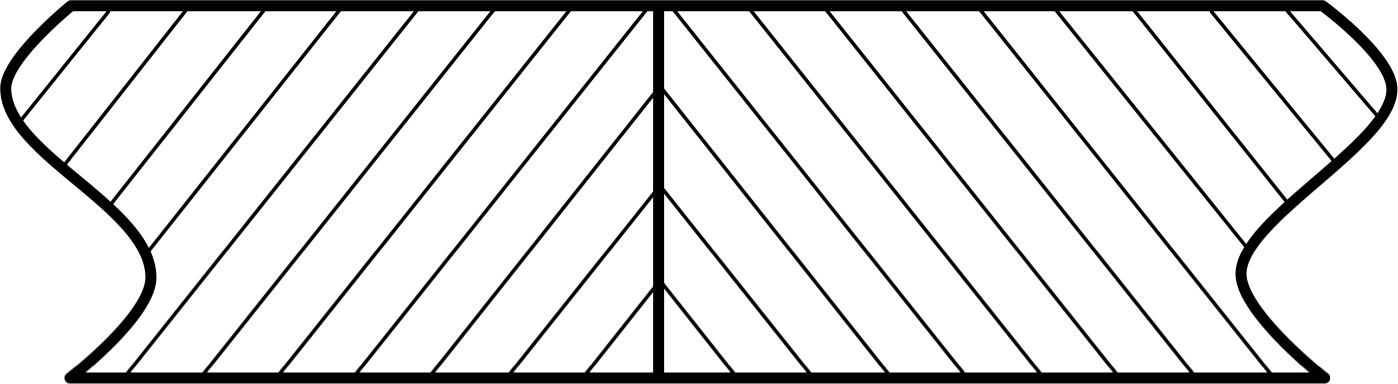

Type 1: Butt Weld with No Reinforcement

While appearing to be the most straightforward weld joint, a butt weld presents multiple challenges and must be carefully set up and executed to meet AMS 2680.

ADVANTAGES

- Components can be made from tubing or sheets with minimal machining;

- No joint fit-up issues if components are precisely manufactured;

- Full penetration can easily be verified by visual inspection;

- Ease of radiographic inspection due to there being no obstruction under the weld.

DISADVANTAGES

- Prone to underfill conditions caused by weld build-up on the underside of the weld;

- Under bead may produce weld spatter, which may be undesirable and may be unremovable;

- Prone to misalignment because there is no self-locating feature to the joint.

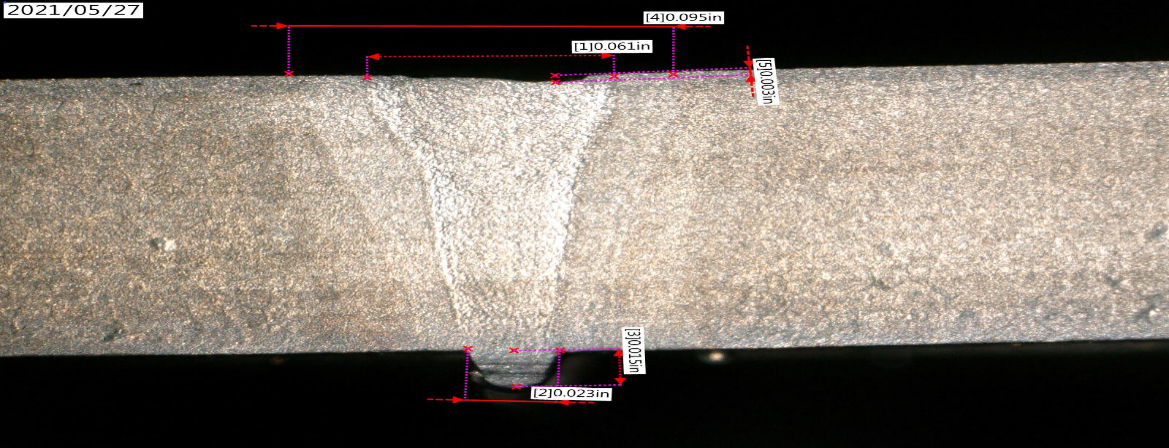

Type II: Butt Weld with Back-up Insert

Often used in aircraft struts, the utilization of a back-up insert in a butt weld can add advantages in the welding process but presents challenges in the inspection. The back-up insert mitigates the risk of burn-through that a butt weld with no reinforcement is prone to, but adds an obstruction to radiographic inspection.

ADVANTAGES

- Components can be made easily;

- Parts self-align;

- No risk of burn through.

DISADVANTAGES

- Difficulty with radiographic inspection due to back-up material interfering with the image;

- Not appropriate for some applications, such as pressure vessels or tubing for flow.

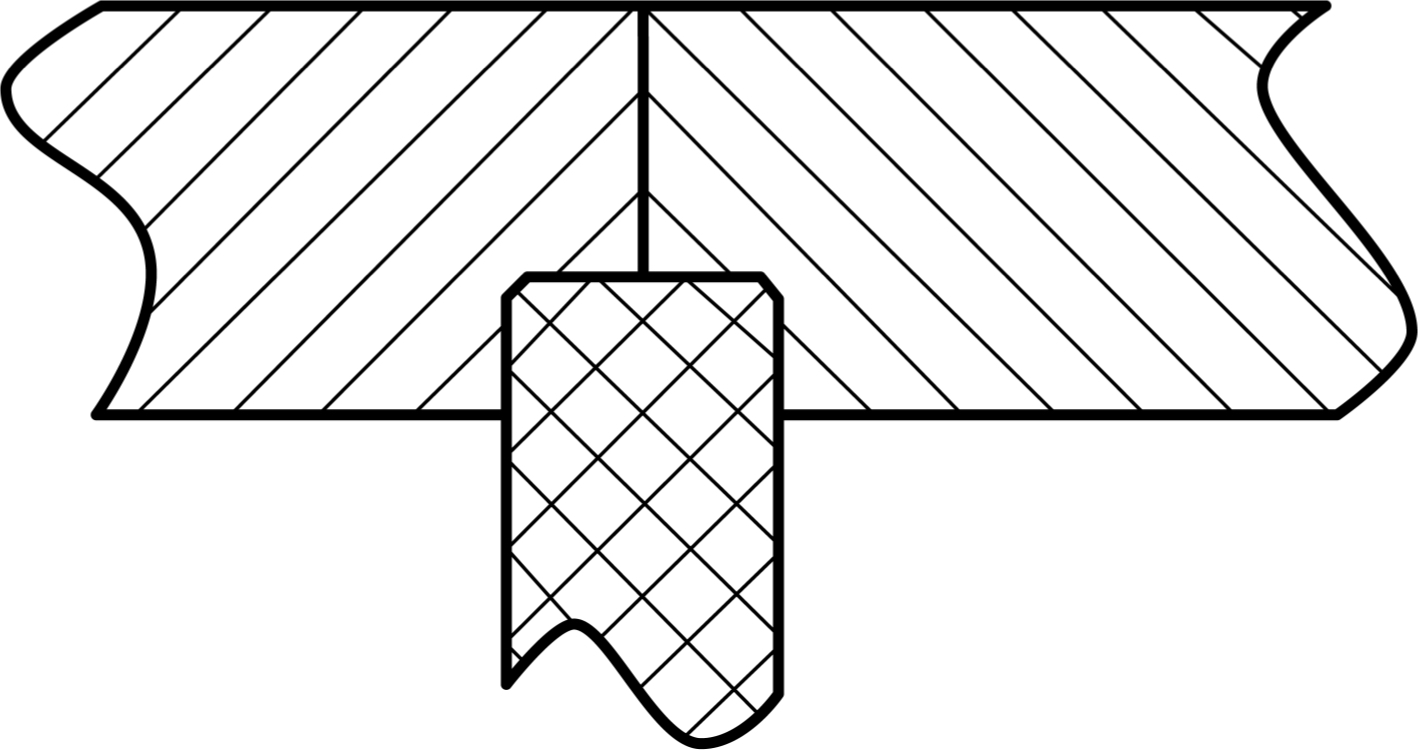

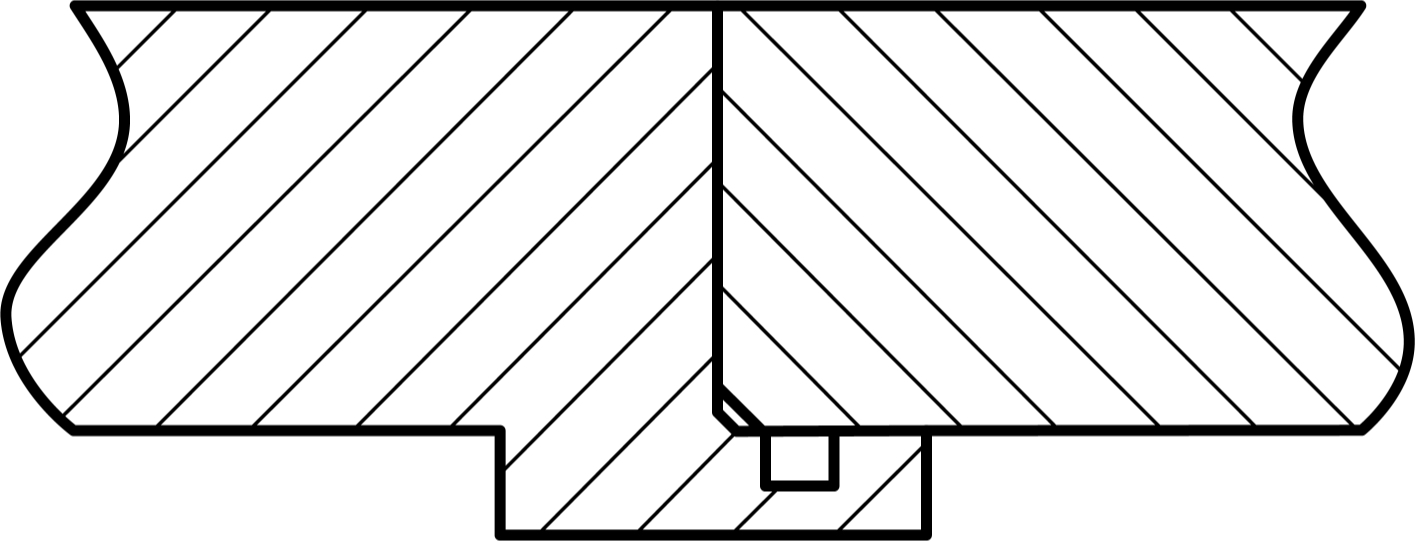

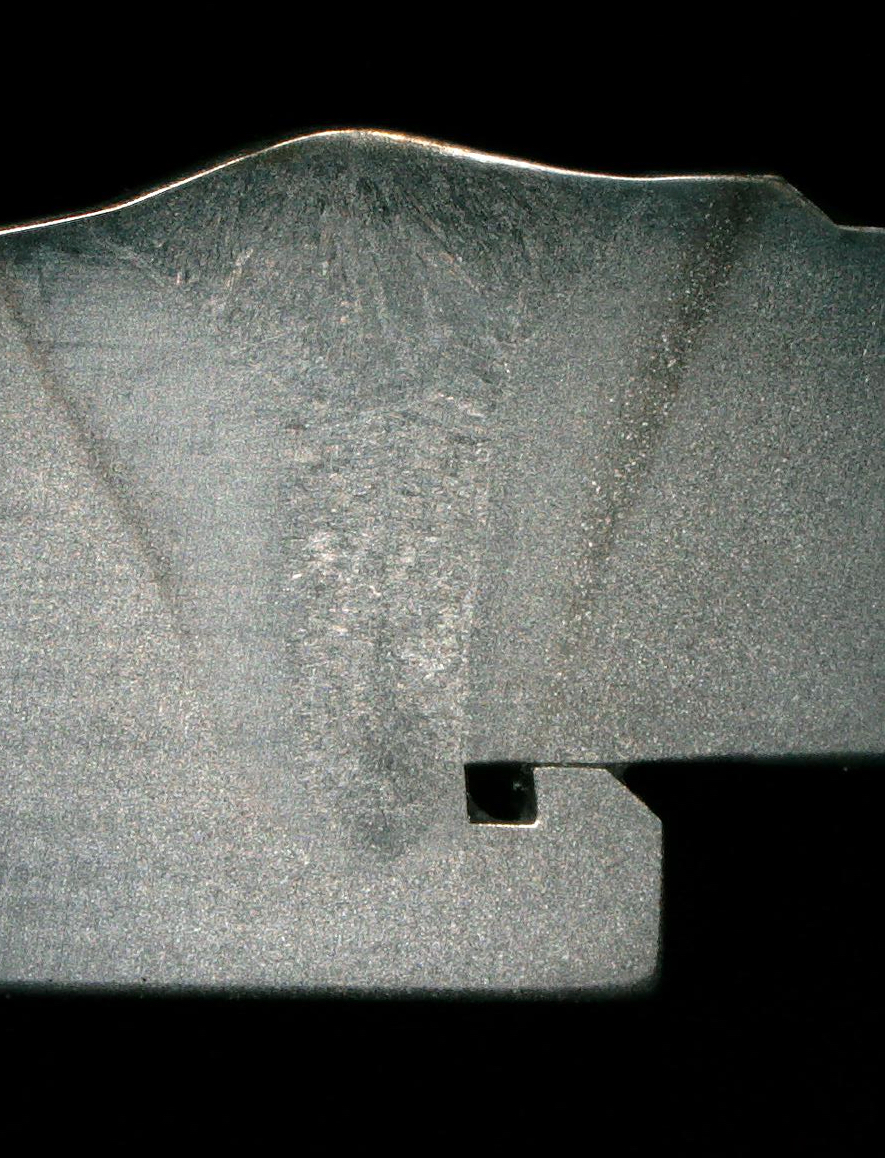

Type III: Butt Weld Backed Up with Stepped Joint

Often used for pressure vessels and tubing with flow, butt welds with a stepped joint can solve many of the issues of the previously discussed welds. The butt welds with a stepped joint create an integrated solution to the risk of burn-through and spatter and keeps testing imaging results clear but does require more time and precision in machining and set up. One important consideration: The beam stop dimensions should be deep enough to allow for a reasonable range in weld penetration and, at the same time, not be so deep as to interfere with a radiographic image.

ADVANTAGES

- Good radiographic imaging due to little back-up material;

- Capable of self-alignment;

- No weld spatter under weld.

DISADVANTAGES

- Weld depth must be precisely controlled to prevent burn-through;

- Complex weld joint requiring precision machining.

Considerations When Welding to AMS 2680

Make sure the part being welded needs to meet the stringent 2680 specification, which is designed specifically for fatigue critical applications, as laid out in the specification. If the part doesn’t need to meet AMS 2680, then consider welding to the less stringent, and less costly, AMS 2681.

Remember that AMS 2680 has specific requirements defined for the qualification of samples. They can be cut from the actual part or from a simulated part composed of the same materials and joint characteristics. You may want to consider that these simulated parts may be preferable to destroying a valuable production part.

The vacuum level when electron beam welding is also an essential factor to consider. While AMS 2681 only requires a vacuum of 1×10-3 Torr, 2680 has a higher requirement of 1×10-4 Torr., which must be adhered to in order to meet the standard. Electron beam welding vacuum chambers take longer to pump down to the higher vacuum level, which ultimately makes it a more expensive weld.

And, of course, a weld designer should not only take into consideration the requirements of the specification but the needs and parameters of the parts’ use. For more help, please feel free to reach out to the engineering experts of EB Industries.