Kovar: an Overview

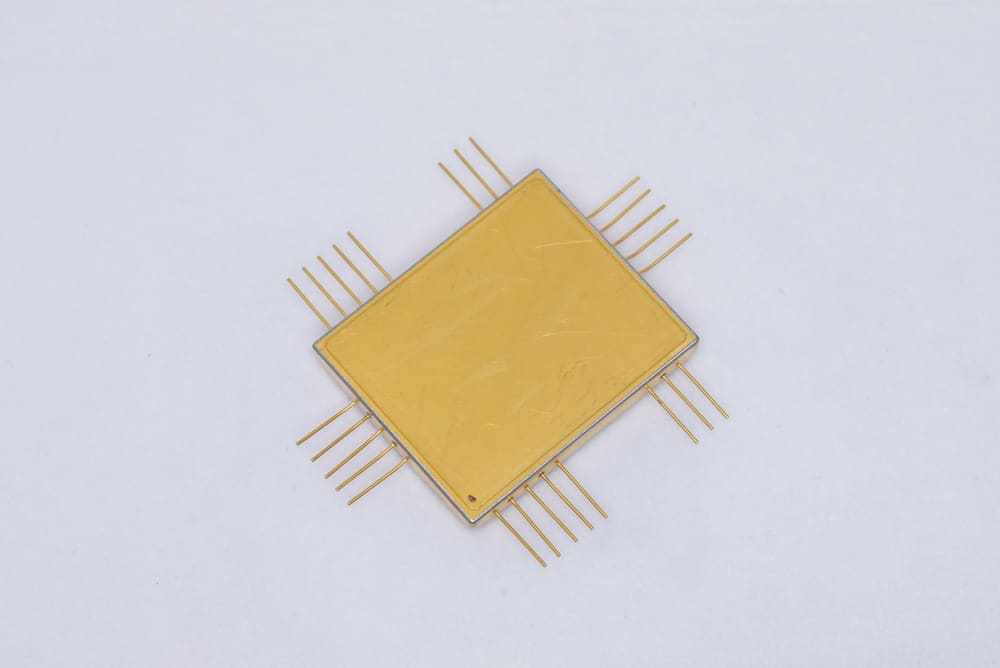

Kovar*, an alloy of nickel, cobalt, & iron, was developed in the US in 1936. It was engineered to have similar thermal expansion characteristics to those of borosilicate glass. This was needed to provide reliable hermetic seals in electrical devices such as lightbulbs, vacuum tubes and cathode tubes. Today, Kovar’s use has expanded into all types of electronics packaging applications, including many that no longer have glass as a package component.

The particular properties that make Kovar-to-glass seals possible, make Kovar a challenging material to weld. Principally, its thermal characteristics require precise control of weld location and heat energy, and its propensity towards oxidation layers demands an exacting cleaning regimen to avoid poor quality, contaminated welds. When cleaned and handled in the proper ESD-safe and FOD-free environments, and welded with a precision laser, Kovar hermetically sealed packages are preferred by numerous industries for the protection of critical parts, especially electrically sensitive components. Laser hermetic sealing Kovar is a cost-effective means of providing a high degree of quality and flexibility in many applications.

The Challenges of Welding Kovar

Kovar was developed to expand at the same rate as borosilicate glass, hence it has relatively low thermal conductivity (17.3 W/m*K) and a melting point (2,640°F/1,450°C) higher than a material like aluminum. These properties yield an alloy that melts easily locally, with poor heat dispersion characteristics. When welded, Kovar is prone to excessive local heat build-up and cracking.

Fusion welding processes, such as MIG, TIG, Laser, and Electron Beam, generate intense heat to melt the material in the desired weld area. Controlling the amount of heat fed into this area is critical for successfully welding Kovar. Manual welding processes, such as MIG and TIG, rely on operator skill and heat sinking to control this heat. Automated methods, such as Laser and Electron Beam, which use computers to control feed rate, power, and target weld location, offer precision and repeatability that result in higher-quality welds.

Kovar and Oxidation

Kovar parts, during formation, are heat treated at temperatures reaching 900˚F, and after cooling, a layer of oxide appears. This oxide layer is purposeful: it improves Kovar’s adhesion to glass, which was the alloy’s original application requirement. But this oxide layer can compromise the quality of welds. Oxides can change the reflectivity of the part’s surface, which interferes with laser coupling and impacts the amount of energy applied. Further, oxides can contaminate the weld pool. Hence, oxide layers must be removed, generally with a mechanical or chemical process depending on the level of oxide post-heat treatment.

Contamination

Contamination is an issue that affects most weldable materials and Kovar is no exception. Decarburization is a process that reduces carbon and removes other surface contaminants and is typically a final cleaning treatment when forming Kovar parts. But decarburization doesn’t necessarily prevent additional contaminants from appearing during any further machining processes.

Kovar does not machine as well as 316 stainless steel, for comparison, and it produces a more ‘viscous’ chip. Consequently, the type of cutting fluid used is important, as well as degreasing and cleaning post-machining. Any contaminant residuals can cause major issues during laser sealing that might lead to irreparable weld seams. The storage and packaging of any machined parts before laser sealing is also critical, as proper storage and packing further reduces the risk of residual contaminants building up and lingering after pre-weld cleaning operations.

Laser Hermetic Sealing Kovar

Kovar, as previously stated, is an excellent material for protecting sensitive electronics in harsh environments, and laser hermetic sealing is one of the best ways to seal Kovar packages. The process is fast and results in clean, impervious welds. Given the heat-sensitive nature of Kovar, a ‘lighter’ weld is used to narrowly focus the heat affected zone. The result is an exceptionally durable hermetic seal, far more rugged, and lighter in weight, than epoxy, soldering, and traditional mechanical seals.

Pre-Weld Preparation and Joint Fabrication

The amount of pre-weld preparation is largely dependent on the condition of the Kovar parts to be welded, and that is generally dependent on the storage conditions and the cleanliness of the machining procedures used to form the part.

To mitigate oxide films and hydrocarbon contamination, Kovar to be laser welded must be thoroughly cleaned. Finished parts typically go through passivation or a chemical cleaning process that removes metals and other contaminants without the use of any mechanical processes. If further cleaning is required, the use of lint-free cotton swabs and delicate task wipes in conjunction with acetone or isopropyl-alcohol to eliminate any remaining FOD is indicated.

Our technicians always handle Kovar parts wearing ESD appropriate gloves to avoid contamination and electrostatic damage. All parts containing electrically sensitive components are prepped in our electrostatic discharge (ESD) safe room with protocols in place to minimize damage from stray electric charges.

Kovar typically goes through a different process than most metals when fabricating a joint. For example, thin covers (measuring as thin as .007’’) are chemically milled to maintain precision and avoid the destruction of critical features that conventional machining might damage. The housings can be milled using traditional methods, but any coolants used should not contain sulfur as it can affect the performance of sealed electronic parts.

Joint Types

Joint configuration is critical as certain parts require a weld directly on the joint while other parts require a weld to be offset. This offset may involve welding .001″ – .004″ toward more material (usually a cover) to prevent the weld from rolling over an edge. This significantly reduces the risk of cracking, especially for Kovar.

Joint Types

- Butt Joint:

- A fit-up tolerance of 15% of the material thickness is desirable.

- Sheared edges are acceptable provided they are straight and square.

- Misalignment and non-flat of parts should be less than 25% of the material thickness.

- Lap joint (burn-through or seam weld):

- Air gaps between pieces to be Lap Joint welded severely limit weld penetration and/or feed speed.

- For round welds in Kovar, no gap can be tolerated unless inert gas coverage can be maintained over the entire weld area.

- Fillet Joint:

- Square edges and good fit-up are also necessary.

- This joint type will require a higher degree of heat to ensure fusion

Fixturing

Laser hermetic sealing requires a precise joint to maintain permissible gaps and reduce mismatch. This reduces the risk of weld nonconformities and damage to internal components. In conjunction with a CNC-guided laser, adequate fixturing is necessary to eliminate the risk of a moving part and ensure the beam is precise and accurate.

Vacuum Baking

Kovar parts that will be laser sealed in our glovebox environments will typically go through some additional steps once they’re in the glovebox system, one of which is vacuum baking. This process occurs in a computer controlled vacuum oven and it results in the parts containing less than 1 ppm of oxygen and moisture. Vacuum baking can be done at various temperatures and durations to meet a wide range of requirements.

Recommended Laser for Hermetically Sealing Kovar

We use fiber optic lasers to hermetically seal Kovar. This technology produces high quality welds and is very controllable via computers and automation.

Our gloveboxes are fitted with computer controlled fiber optic lasers as well as oxygen and moisture monitoring, the data of which can be recorded for gas analysis and reportage. Integrated vacuum ovens have inert gas drying with purification and recycling capabilities. Supporting equipment includes laminar flow work benches and exhaust hoods.

Laser Hermetic Sealing Modes of Operation

Laser beam energy can be applied to the workpiece either as a series of pulses or in a laser stir weld configuration. The decision to use a particular method is dependent on the application, the properties of the materials, etc.

Pulsed Laser Hermetic Seal

Commonly, welds are accomplished with a pulsed laser, which utilizes a beam that is switched on and off at a very high rate (10-1000 Hz), such that the energy applied to the work piece is a series of separate bursts. Each pulse creates an area of melted material, the workpiece is then moved slightly, and another pulse is applied, resulting in a series of overlapping welds that create a continuous bead. Each weld area created by a pulse cools quickly and minimizes the amount of heat in the surrounding material. Limiting the transfer of heat within the part reduces the risk of damage to electrical components and the distortion of the part.

Laser Stir Welding

The standard technique when welding crack sensitive alloys, like Kovar, is to use a filler wire or shim made from a more weldable alloy (such as 4047). For welding heat-sensitive components, such as electronic housings, using filler materials and welding with a pulsed laser is generally indicated. However, for welds with deeper penetration in crack sensitive alloys, we’ve had a lot of success using our proprietary Laser Stir Welding technique.

Laser stir welding is a process in which a continuous beam laser oscillates at a relatively high frequency, which causes a stirring action within the molten weld pool – hence the term “stir welding.” The result is a manipulation of the weld pool which changes some key characteristics of the weld.

Benefits:

- Laser Stir Welding results in largely defect-free joints, with no hot cracking, porosity or solidification cracks.

- More precise control of the weld pool for increased keyhole stability.

- Improved control over the geometry of the weld – as an example, joints can be designed with more width at the root of the weld, which can be very useful for Lap/Thru-/Blind welds.

- Weld profiles can be manipulated into asymmetry, such as increasing the penetration on one side of the weld joint.

- Patterns can be programmed to compensate for large gaps in weld joints and other potentially problematic weld geometry problems.

- Higher feed rates can be achieved than with pulsed laser techniques.

- Filler material (wire or shim) is typically added manually before welding.

Cover Gas Requirements for Kovar Welding

Cover gases are often required when hermetically sealing Kovar, and the gas used can be a critical decision. The use of the wrong cover gas can result in access plasma generation and/or changes to the properties of the welded materials. Generally, cover gasses are selected on a per project basis, but a few general guidelines are:

- Argon: commonly used and can minimize plasma generation, Argon should not be used with C02 lasers exceeding 3kW of power to further reduce plasma generation.

- 90-10 Nitrogen – Helium: commonly used in housing assemblies, the helium tends to suppress plasma generation, and since it is very lightweight it can require a high flow rate, which can cause weld pool turbulence, which is undesirable.

- Argon – Helium Mixtures: recommended for most general laser welded applications depending on laser power level.

- Nitrogen – C02 Mixtures: can produce acceptable welds although often the seam will be slightly oxidized.

Generalized Process for Hermetic Sealing a Kovar Package

Kovar is often called out for applications containing sensitive electrical components that are destined for a demanding environment. Careful handling of Kovar parts is essential to successful hermetic sealing.

At the start of the process, our qualified and highly trained operators ensure the proper calibration of all equipment utilized. ESD precautions are put in place per industry standard specifications and customer requirements before any handling of the parts occurs.

Once components are ready to be processed, a common step, but not required, is to perform a face-down leak test, which verifies the integrity of ports found on the unit, such as feed-thrus or connectors. The parts are then cleaned using acetone following proper procedure before the covers are manually tacked in place using a laser.

Depending on the requirements, the parts are then vacuum baked at high temperatures to mitigate oxygen and moisture issues. While this step can be lengthy, it greatly increases the chance of successfully sealed units. Once the bake is done and any pertinent data is recorded, the parts move into the welding area of the glovebox environment.

Using rigid welding fixtures, the parts are squared off to ensure a true and repeatable weld of all covers to the housings and hermetically sealed with an automated laser routine. The parts are further cleaned if required and visually inspected per industry standard specifications.

Depending on the requirement, parts may go through a series of inspections and tests post-weld.

Fine Leak Testing: Our glovebox welding environments contain a standard 10% Helium that EBI can adjust to a specific requirement, some of which is sealed into the part during welding. Fine leak testing can then detect leaks of that helium by utilizing a helium mass spectrometer in a special testing environment.

Pressure Bombing: This step exposes the completed parts to helium for an extended period in a specialized test environment, which can locate leaks again using a mass spectrometer to detect larger leaks.

Gross Leak Testing: Leaks that are too large to be detected using pressure bombing or fine leak testing can be subjected to gross leak testing. The parts in question are exposed to Fluorinert FC-72 under pressure. The parts are then submerged in a bath of FC-40, which is a similar liquid with a higher boiling point. The FC-40 is then heated, which causes the FC-72 to bubble out from any units with leaks, which is visible to our operators.

All testing is done in accordance with MIL-STD 883 Method 1014, MIL-STD 202 Method 112, and MIL-STD 750 Method 1071.6.

Finally, the parts are cleaned and packaged carefully with ESD precautions still in place to ensure parts are returned safely to our customers or sent to the next link in the supply chain.